We can guide you through the factory,or you can explore on your own

To help you get acquainted and learn about traditional soy sauce production factories, our entire self-tour route is included below. Enjoy your virtual tour!

1. About Kuyo-gura

Kuyo-gura is the soy sauce storehouse owned by Yuasa Soy Sauce Ltd. You are able to see the whole process of soy sauce production here.

In this tour, you will learn the history of soy sauce, see Japanese cedar barrels and the filling and pressing equipment, and you will taste our products. You can try stirring the mash with a special paddle, just like a professional, for an extra fee. If you would like to try stirring the mash, please pay at the counter located at the entrance.

The final destination is the souvenir shop “Hishiokan”. Feel free to enjoy your souvenir shopping here.

● Inside Kuyo-gura

● Attention

Please ask the nearest staff if you need assistance with mobility. You can also enjoy shopping at Hishiokan (8) or rest at café Hishio (9).

The restroom is located at Hishiokan (8), near the entrance/exit.

2. Kuyo-gura entrance

Enjoy observing the entire process of Yuasa Soy Sauce production at Kuyo-gura – a birthplace of Yuasa soy sauce.

After entering the storehouse, the tour is directed as follows: 1st floor→2nd floor→covered passage→1st floor. If you have trouble using stairs, please ask our staff nearby for assistance. You may also wait at Hishiokan (8).

3. Japanese cedar barrels and history of soy sauce

At the front of the soy sauce storehouse, you will first notice cedar barrels containing soy sauce. These barrels are over 100 years of age. Soy sauce is prepared through a 1-2 year fermentation period.

● History of Soy Sauce

Back then, Yuasa had ample supply of natural and clean water, thus Kinzanji miso production flourished. Soy sauce was produced by refining tamari, which is nutrient-rich liquid naturally created in the process of Kinzanji miso preparation.

● Japanese Cedar Barrels

4. Factory (Pressing)

This is where we extract the soy sauce from the moromi, which was fermented in cedar barrels.

Filter cloth is spread inside a wooden frame, and moromi is spread on the cloth, which is then folded shut. This is repeated 300 times to form a neat stack.

The stack’s weight naturally starts to press the soy sauce through the filter cloth. This naturally extracted soy sauce is called Ki-joyu.

We let this process continue for one day. Then we lower the pressure plate to rest on the stack, and wait half a day to one day. Over the next 3-4 days we gradually increase pressure as more soy sauce is extracted.

The purpose of the very slow pressing is to avoid the extraction of cloudiness, which negatively impacts flavor.

After the soy sauce is extracted, it is moved to the wooden barrels you see beyond the pressing machine to age a little more. Then it is filtered and pasteurized.

5. Moromi (main fermenting mash), Cedar barrels

Moromi (main fermenting mash) is alive. This is an old-fashioned soy sauce production method.

● Manufacturing Process

Soy sauce brewing is started by adding Koji mold seed to an equal mix of steamed soybeans and toasted wheat and allowing the mold to grow for a few days. Then this Koji mix is placed in a tank with salt brine to create the Moromi, and it is fermented for approximately 1 to 2 years.

Osmophilic yeasts and their enzymes, lactic acid bacteria, etc., help break down the ingredients and further maturation creates the distinctive color, flavor, and fragrance of soy sauce. Frequent stirring provides air to these microorganisms.

Typically, soybeans are steamed; however, in the traditional method they are boiled slowly and the boil water is used to make the salt brine. In this way, soybean nutrients including isoflavones, lecithin, and saponin are fully extracted.

The preparation of the soy sauce typically starts in winter and follows several steps as follows: letting the mixture mature in the natural cedar barrels for over a year, squeezing Moromi, transferring the raw soy sauce to large wooden vats, and precipitating impurities out of raw soy sauce. At the end, the liquid emerges on the top layer becomes soy sauce.

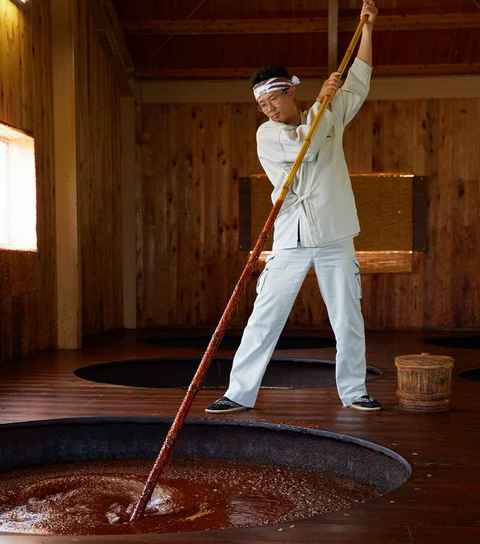

6. Moromi stirring with wooden paddle

Try stirring the moromi in a cedar barrel, using the traditional paddle!

Please come to the counter near the shop entrance to apply.

You will need to wear a hair net, and wash and sterilize your hands.

We provide traditional clothes so you can take a souvenir photograph.

Stirring: 300 yen

Discount package: Stirring: 100 yen, soft-serve soy sauce ice cream: 300 yen, total: 400 yen

7. Soy sauce filling area

The soy sauce produced in the storehouse is bottled here. The final product is shipped all over the world.

Final process: Pasteurization

The soy sauce produced at Kuyo-gura goes through pasteurization, then is bottled for shipment. Using special pasteurization equipment, we ensure a safe and high quality soy sauce for our customers.

8. Hishiokan Souvenir Shop

There is a wide variety of goods in Hishiokan, including Michelin chef-recognized pure black bean soy sauce, the Rosanjin soy sauce, Curry soy sauce, and Kinzanji miso, which is Yuasa’s local specialty.

Sampling is available, so please feel free to try all of our products and explore the varieties in flavor.

9. Cafe Hishio

Rest area offering soy sauce ice cream.

Please feel free to rest here.

At Café Hishio, please try our one-of-a-kind soy sauce ice cream, which is very popular among visitors. There is soy sauce in the ice cream, but if you enjoy a richer flavor, feel free to put a little more on top of your ice cream.

10. Marushin Honke

Gifts and Kinzanji miso sold in bulk

At the Marushin Honkei shop you can buy Wakayama souvenirs and Kinzanji miso in bulk. There are also other food items, and amazake, a sweet drink made from Koji rice.

Gift-wrapped items can be purchased. Domestic shipping is available.